Mechatre: Training center design for future station technicians

Nestled under elevated Shinkansen* tracks in the railfan mecca of Omiya lies the JR East Mechatronics Mechanical Equipment Technical Training Center.

Unique site characteristics have set a fresh scene for training tomorrow's technicians.

*Bullet train

- JR East Mechatronics

Mechanical Equipment Technical Training Center - Location: Saitama

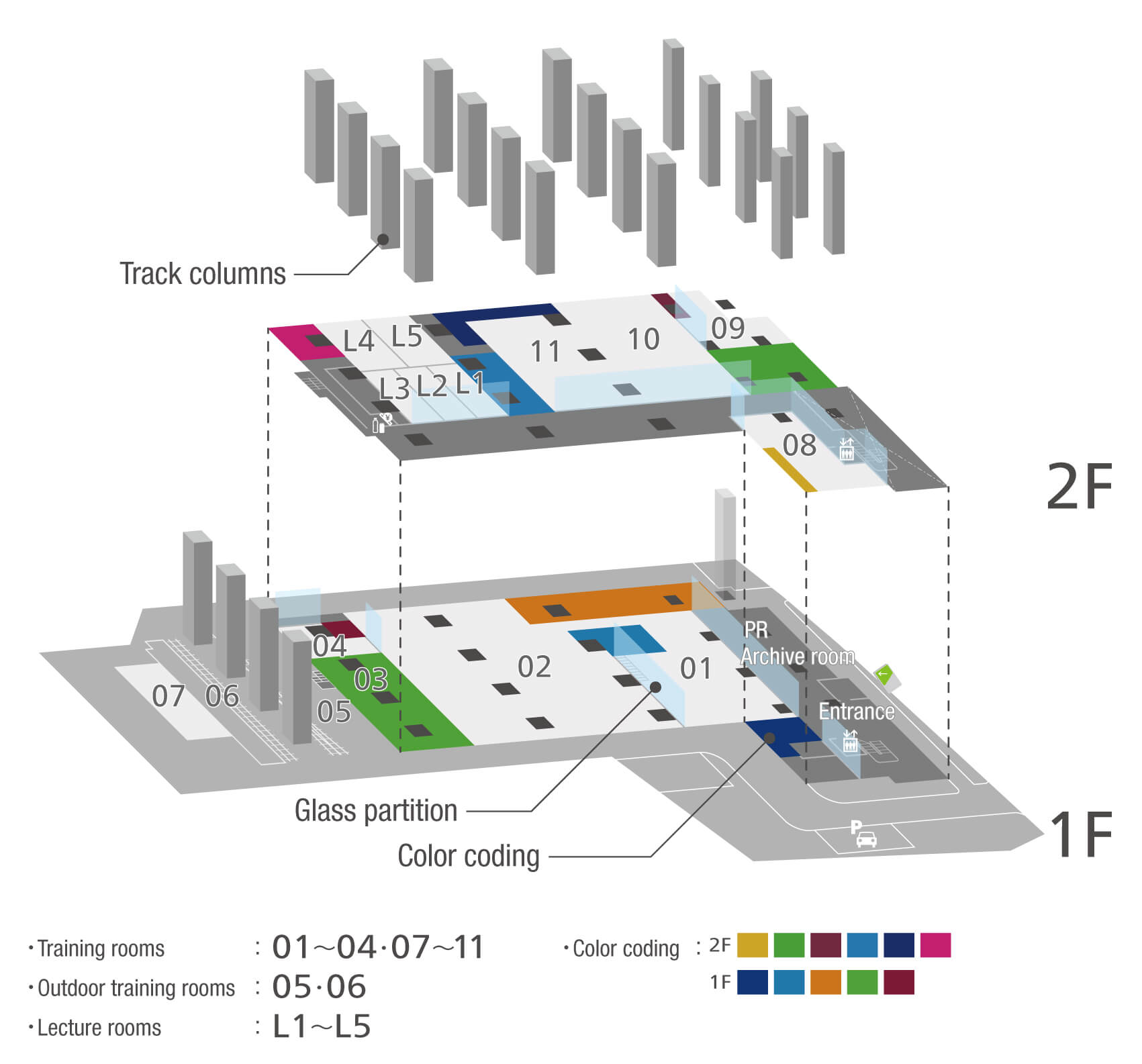

Floors: 2F+1F

Total floor area: 4,640.60m² + 119.78m²

Structure: S

Completion: 2021

A new training center relocated from Oimachi in Tokyo

Technical services developer JR East Mechatronics makes station equipment such as platform doors and elevators, as well as an array of solutions using Suica prepaid cards. With their parent company JR East, JREM envisioned a new training center focused on these systems and inspired by a forward-looking commitment to cultivating human resources who will contribute to society after honing this knowledge and expertise.

Mechatre covers more ground than a previous site in Oimachi that it replaces, and it will serve more trainees. Having trainees see, touch, and experience these systems was essential, but offering a practical training facility with actual station equipment was only the start. The planners sought a multifaceted learning environment that would also include a new archive room introducing past, present, and future JREM initiatives. Safe operation of these systems also calls for well-rounded training. Participants must learn about mechanical structures, maintenance, quality control, and other matters. That's why a more realistic training center was proposed, modeled after actual train stations.

The first floor recreates a platform and the second a concourse. Working equipment here includes platform doors, ticket vending machines, and ticket gates. To reproduce the experience as faithfully as possible, the floors are linked by typical station escalators and elevators. Even snow-melters can be found on-site. Overall design and construction supervision has enabled technical training on all equipment supporting railway operations.

Designed to make the most of track columns

Conceptually, the center was intended as a seamless space supported by technology. Moreover, its design would explore three themes: development of future station technology, a center capable of creating future stations, and an open center where creative human resources are fostered. The center is located under elevated tracks next to the Omiya General Rolling Stock Center, which also reflects an earnest wish to cultivate future technicians here in Omiya, a cradle of railway development in Japan.

Design and construction for a site below elevated tracks did present some challenges, however – especially the concrete columns. Some 19 columns were targeted for inclusion in the building, but it took trial and error to make the limited area available feel spacious, bright, and intuitive without interfering with them. For minimally obstructed views and a sense of spaciousness, no effort was made to conceal the columns, which remain as part of the building's framework.

Left: A platform door training room. For maximum training space, the #2 track column at left was left exposed.

Right: A snow-melter training area between columns outside.

Heightened spatial awareness, from a bold color scheme and signage system

Elevated tracks inevitably cast shadows, and the columns tend to reduce visibility, but here, glass walls provide light and create a sense of openness. The rooms and spaces also appear brighter from the color scheme, which is based on a white background.

Visibility inside is improved by color-coded walls. Walls of rooms not used for training (such as restrooms or storage areas) are painted in bold, vibrant colors. Even in rooms interrupted by columns, the plan called for eye-catching colors, to lead people to their destination.

Each training area is numbered in the signage system. Prominent number lettering is visible even from a distance, making it easier to find one's way. Because the center includes a simulated station, it also has some station signage. Center signage is distinguished from station signage by the large lettering on columns, in design that recalls research labs.

Left: Rooms are mainly white, but the large signage and vibrant, color-coded walls are eye-catching. This work was awarded in the 55th SDA program of the Japan Sign Design Association.

Right: Columns display center signage, while signage for the simulated station is suspended from the ceiling. Both their appearance and the underlying signage system make it easier to tell them apart.

Structural and facility design below elevated tracks

The preexisting columns also complicated structural design, especially for the substructure. To keep the building load off the column foundations, the plan called for long-span footing beams straddling the foundations. However, normal reinforced concrete beam design would have made the beams too large for the floor height needed. For this reason, prestressed reinforced concrete beams were used for some of the footing beams. This enables long-span footing beams of a suitable size.

Another challenge was the sound carried from the elevated tracks. Here, it was not possible to block all sound from passing trains. For a measure of sound absorption and insulation, sandwich panels were used for part of exterior walls, but because this alone would not provide complete soundproofing, other steps were also taken to suit the soundproofing needed in each room.

Where ample height was required, structural members and building fixtures were left exposed instead of concealing them behind a ceiling. But even in this coolly mechanical setting simulating a station, great care was taken to keep the equipment, piping, and wiring appealingly neat and orderly.

A place to nurture budding technicians

Externally, graceful flowing Shinkansen lines are reflected in horizontal metal sandwich panels. These lines along with horizontal rows of windows were intended to harmonize with the trains themselves, running on the elevated tracks.

Trainees enter through a two-story atrium, bright and open from the glass curtain walls. By design, the entrance provides an exciting segue to their training. Maximum use of glass walls inside seamlessly links the areas and provides unobstructed views of all the technology at work. A comfortable second-floor lounge invites trainees who come from across Japan to relax and get to know each other.

The nickname Mechatre hints that this building is a training center both for JR East Mechatronics and for mechanical engineers of the JR East Group as a whole. Learning techniques for safe, reliable operation of station equipment is only part of the goal of Mechatre, which is also intended to foster technicians ready to contribute to society through the new technical services they will create. Those trained at the center today will be tomorrow's railway professionals.